-

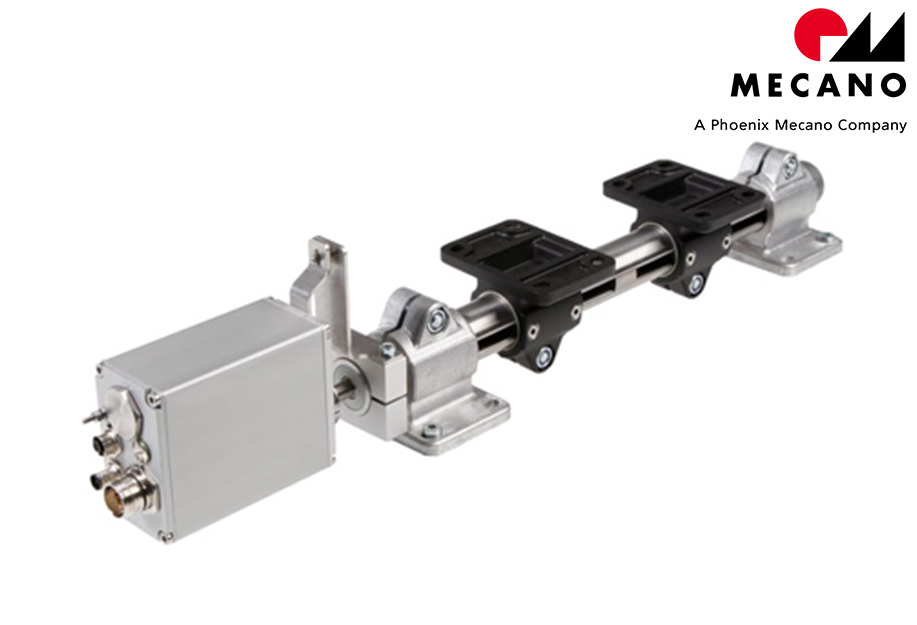

E single-tube linear actuator

Features:

■ Linear actuator for light to heavy moving applications

■ Sizes (30, 40, 50, 60) can be combined

■ Comprehensive range of accessories

-

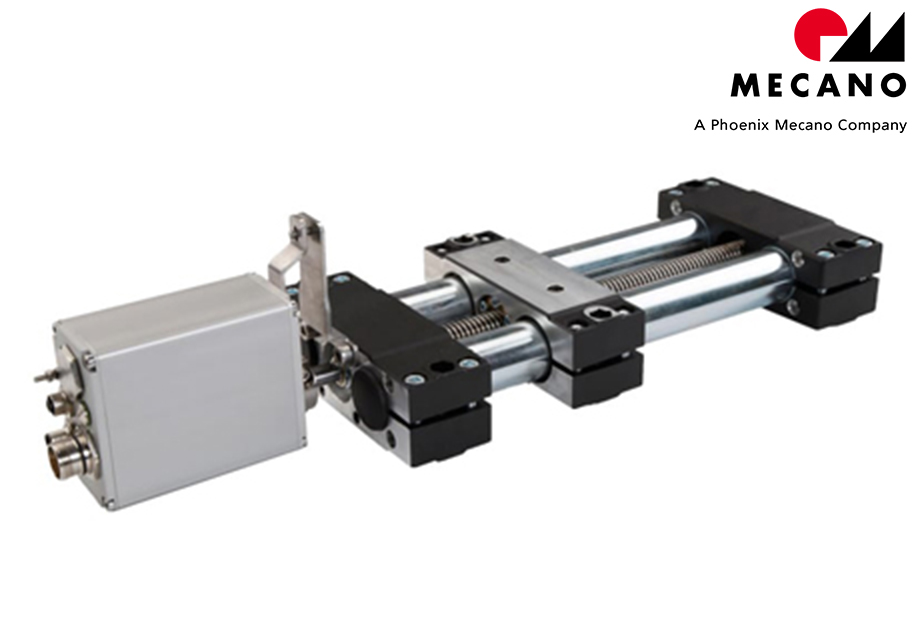

EP(X) Tubular linear unit

Features:

■ Linear actuator for supporting high torques

■ Version with large fixing plate available (EPX range)

-

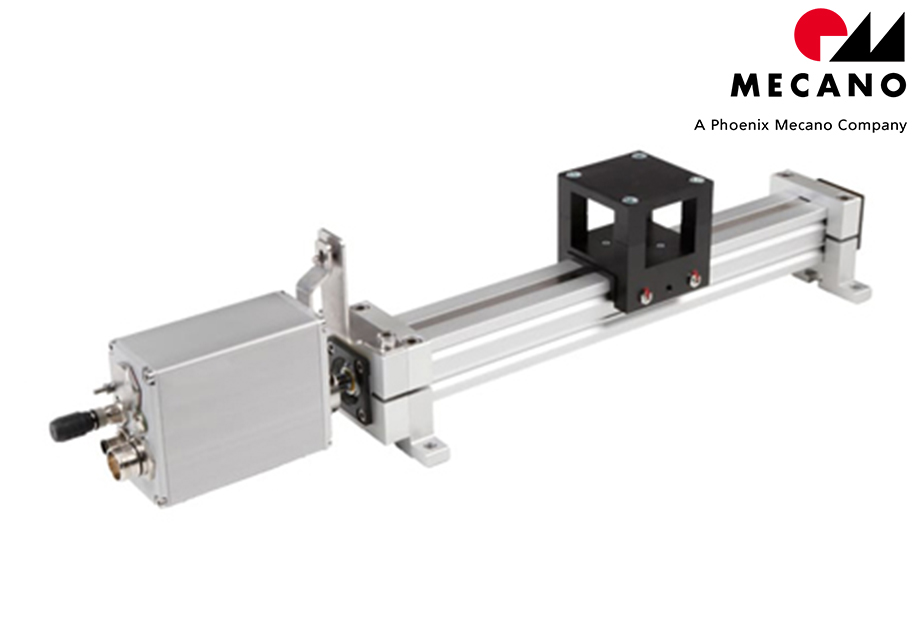

Quad® EV profile linear unit

Features:

■ Spindle covered by steel band

■ Wide range of available carriages and fixing elements

■ Comprehensive range of accessories

-

SeGMO actuators for linear actuator automation

Lenord+Bauer offers a modular application for the automation of linear actuators, consisting of:

■ Fully automated drives SeGMO-Positioning and SeGMO-Motion

■ Electronic control unit SeGMO-Box for up to 5 actuators

■ Pre-packaged software modules SeGMO-Lib

■ Single-cable wiring (hybrid cable) SeGMO-Connect

■ Complete retrofit set SeGMO-TouchBox

-

SeGMo - actuators for RK Rose+Krieger linear actuators

■ Non-wearing, brush-free 24 V DC motor and compact spur gear

■ Sturdy housing in aluminium or stainless steel

■ Magnetic multiturn sensor for precise positioning

■ Integrated joystick for setup without PLC programming

■ Wide temperature range from -10°C to +60°C

-

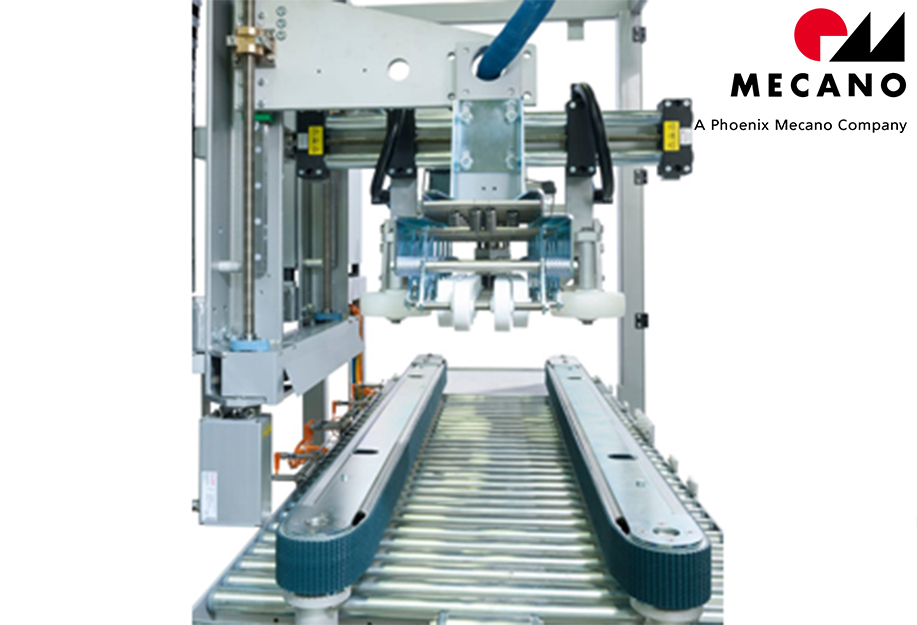

Time-consuming manual setup and adjustment work is no longer required thanks to automated format adjustment

With a range of different adjustment points, frequent product changeovers and small batch sizes, the new construction of packaging machines and production lines is the perfect opportunity to plan and network automated format adjustment solutions. But there is also a huge potential for increased efficiency in existing systems. Retrofitting is an obvious choice for production systems where components still require time-consuming manual adjustment work, such as adjustment wheels, guides with clamping devices or cylinders with limit stops.

As well as the time factor, the increased quality and reduction of waste when the system is re-started following a format changeover also cannot be underestimated. The more manual format adjustments are installed in a system and the more complex the system as a whole, the quicker the investment in an automated positioning solution will pay off. The RK Rose+Krieger linear actuator modular system and the Lenord+Bauer actuators make automation quick and easy to achieve.

Our experts will be happy to support you with the implementation!!RK Rose+Krieger and Lenord+Bauer benefit from the synergies that arise from the sensible combination of their product ranges

Automation specialists RK Rose+Krieger GmbH from Minden and Lenord, Bauer & Co. GmbH from Oberhausen both work together to meet customer demands for fully automated infeed axes. The linear units and actuators complement each other perfectly. The linear units and actuators complement each other to create a practical complete package.

The package features single-tube linear actuators E, twin-tube linear actuators EP/EPX, and profile linear actuators quad® EV from the Move-Tec range. There is then the option of a short or long actuator with either an aluminium or stainless steel housing. The devices provide a rated torque of 3.5 Nm or 5 Nm.

Lenord+Bauer offer the torque supports necessary in fitting the SeGMo´s to the corresponding linear actuators. Once the torque support has been fitted, the actuator is simply placed onto the axis and pushed into position. A clamping ring fixes the drive firmly onto the drive shaft of the linear unit. In addition to the positive shaft connection, a flexible motor support also forms the necessary floating bearing on the torque support.The actuator can be used either as stand-alone components or as a modular overall system, and can be directly plugged into the machine control system using the integrated fieldbus interface. The only things then needed to commission the linear actuator with automatic adjustment are a 24 V power supply and connection to the bus communication.

The two companies also work in close collaboration to fit even complex machines with multiple linear units and a local communication unit. In these cases, actuators with hybrid cable and a SeGMo-Box are used, along with a compact PLC control system with operator terminal.

Both of these are supplied by Lenord+Bauer on request, in the form of a connection-ready module with operator software included. Integration into an existing control environment is really simple, as the SeGMO-system supports standard interfaces such as PROFIBUS and PROFINET.

Please Scan The QR Code

Copyright © 2020 Mecano Components (Shanghai) Co.,Ltd.All right reserved 沪ICP备05020652号-1  沪公网安备 31011402006483号

沪公网安备 31011402006483号

Copyright © 2020 Mecano Components (Shanghai) Co.,Ltd.All right reserved 沪ICP备05020652号-1  沪公网安备 31011402006483号

沪公网安备 31011402006483号

Back

Back